EXCLUSIVE PRODUCTS

EXKLUSIVE PRODUKTE

Most of the products in the BKT range are manufactured with our own moulds and are freely available. However, there are always requests for unusual special solutions or products with special packaging functions, which we then develop together with toolmakers on behalf of the customer. Some customers then insist on exclusivity, but other products are also free for alternative uses or there are restrictions for certain industries or filling products.

READ MORE

Exclusive products are often newly developed in close cooperation with the customer. Product and manufacturing optimization is often carried out together with specialized designers and toolmakers and in close dialogue with the customer.

In some cases, injection moulds or blow moulds BKT are provided by the customer and are precisely adapted to the existing production machines and peripherals. The type of cooperation for these special projects is specifically and precisely tailored to the customer’s wishes. The financing of e.g. new moulds will be agreed upon project specifically depending on the exclusivity requirements.

Development of special packaging solutions

Again and again we are asked to develop and produce special or exclusive packaging solutions. In close cooperation with the customer, designers and toolmakers if necessary, we are happy to develop customer-specific solutions.

With our modern blow and injection moulding machines and handling robots we can cover a wide range of possible packaging products. BKT’s speciality is to react quickly and flexibly to customer requirements and to produce even smaller lot sizes reliably and with high quality.

Furthermore we produce with new or already existing customer moulds on our injection or blow moulding machines. If necessary, tool adjustments for our machines can be made.

Examples of such projects have been successfully implemented in recent years in both the injection moulding and blow moulding sectors:

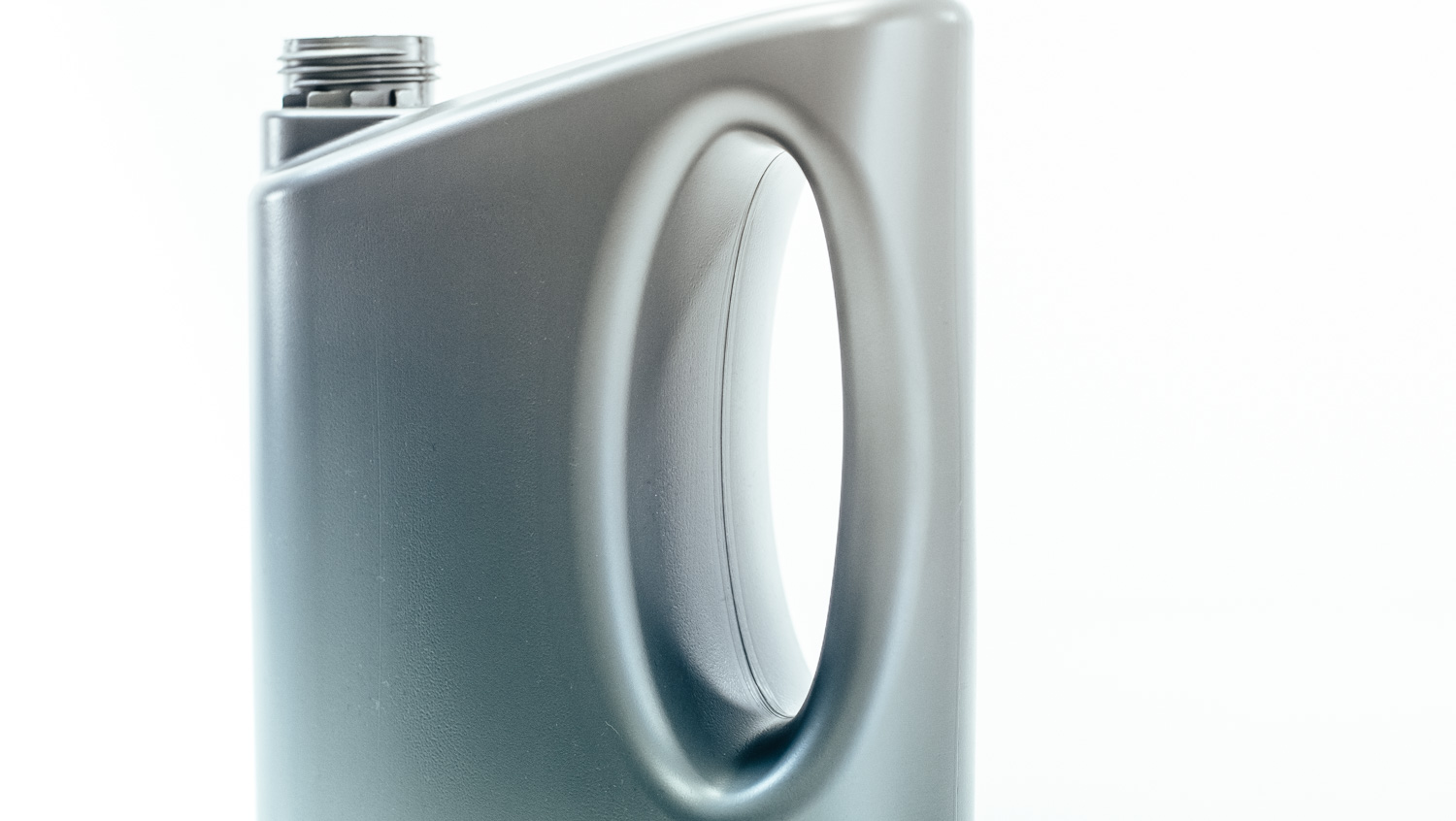

Canister Family

Together with a German developer and producer of high performance lubricants, 3 blow moulding tools for the production of canisters were developed. The canisters have a filling volume of 1 liter, 4 liter and 5 liter and are all produced with a viewing strip for level reading.

READ MORE

The customer attached great importance to an unmistakable and stable corporate design with high recognition value, good labeling and ergonomic handling in use.

Olive Bowl with Lid

Together with our distribution partner Celeris from Belgium these olive containers were developed. The French bottler and distributor had very strict specifications regarding design (derived from an antique olive container) and above all stability and sealability of the bowls. Here, moulds with two or four cavities for the bowl and lid were designed and built.

Handle Bottles (Primo Series)

BKT produces the modern plastic bottle series made of HDPE for its long-time partner Logo-Plastic AG from Switzerland using customer tools. The ergonomic grip bottle can be produced with volumes of 1.5 litres, 2 litres, 3 litres, 4 litres and 5 litres, in the “Ad Blue” version also with an inserted filling hose.

READ MORE

Beak Canister

We also blow beaked canisters with a volume of 5 litres using tools from Logo-Plastic AG. Several screw cap versions are available for the filling opening. The reclosable pouring opening can be supplied with a screw cap DIN 16. Colours or different insert weights can be realised on request.

Shovel Lid and Shovel

For example, for fertilizers, de-icing salt or other spreading materials, the practical shovel lid was developed together with a customer. It can be used on all BKT packaging buckets from 8.5 litres to 11.4 litres as a sealing lid. In order to facilitate the spreading of the bucket contents, a shovel, which is also injection moulded at BKT, can be inserted into the recess of the lid.

Shaker

The BKT spreader is also extremely practical for spreading and bulk materials. It has a capacity of about 3 litres. The ergonomically designed handle facilitates the even and dosed spreading of the spreading material. The perforated lid can be closed with a hinged closure.

Jugs

Exclusively on customer’s own tools BKT has been producing screw cans and partly also the screw cap lids for years.

READ MORE

Dispenser Bottles

Again exclusively with customer-owned tools we blow various bottles and cans for dispenser systems. These are usually used for skin protection, skin cleansing or skin care products.

Boxes and Lids

Also on tools of our partner Celeris we produce various cans and trays of different sizes and shapes. The colour design of these products can be individually tailored to customer requirements.